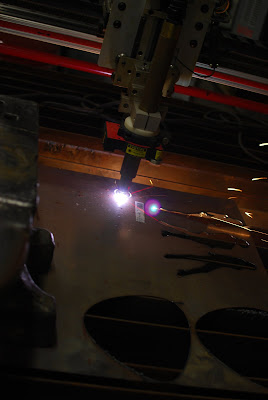

super nice to be able to mess around with the plasma table. today was learning how to dial in the crude software for different materials and thickness. now i need about 60 tons of .25" thick plate to make stuff with. wish that was free....

silouhettes of bettie page and messing with the kind of consumables on kobologo. this thing doesn't make super fine cuts, but a lot better on thinner metal when using the 60amp consumables instead of the 80amp consumable, something i never knew before. seems like i can make a cut as thin as .060", not too shabby. still feels like the machine would much prefer to have a huge 4 x 8' slab or steel on it though.

also finally figured out how to use the torch height control and set point on the machine, something else i never knew how to use before. so it should potentially be able to cut metal on uneven and curved surfaces. it measures the voltage of the plasma cut to determine how high the torch should be riding along the metal, and can adjust this in real time while cutting. the best part is when cutting thinner metal though, now the machine doesn't crash into the sheet as it warps from the heat, it rides right along with it.

No comments:

Post a Comment