i'm not sure what these are for, but franklin wanted to test them out. good stuff, the more i test the better i learn how to make this thing do what i want.

Wednesday, March 10, 2010

wishbones

i'm not sure what these are for, but franklin wanted to test them out. good stuff, the more i test the better i learn how to make this thing do what i want.

Sunday, March 7, 2010

matt's bottle opener.

matt threw in a ton of help figuring out and making the ventilation happen for the plasma cutter. he was saying how i need to cut him out a bottle opener when i got the table up and running. so i spent a little bit extra time and drew this up quick and cut it out. i drew it in the computer without really making any mockups or doing any looking around first, so the thing came freakin' huge. but yes, it does open a bottle of beer. hell if you couldn't get the bottle opened with this sucker, you can just break the top off the bottle with it. or lunk upside the head the guy next to you making fun of you for not being able to open the damn beer bottle in the first place.

so matt, i'll work on making a better one for you, but at least made a starting effort....

shop sign.

cut out a sign for ikkai shop door. out of some old scrap steel i stole from franklin, i'm kinda liking the colors...

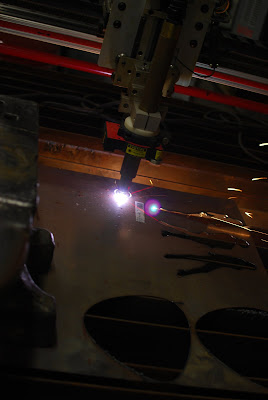

plasma testing.

super nice to be able to mess around with the plasma table. today was learning how to dial in the crude software for different materials and thickness. now i need about 60 tons of .25" thick plate to make stuff with. wish that was free....

silouhettes of bettie page and messing with the kind of consumables on kobologo. this thing doesn't make super fine cuts, but a lot better on thinner metal when using the 60amp consumables instead of the 80amp consumable, something i never knew before. seems like i can make a cut as thin as .060", not too shabby. still feels like the machine would much prefer to have a huge 4 x 8' slab or steel on it though.

also finally figured out how to use the torch height control and set point on the machine, something else i never knew how to use before. so it should potentially be able to cut metal on uneven and curved surfaces. it measures the voltage of the plasma cut to determine how high the torch should be riding along the metal, and can adjust this in real time while cutting. the best part is when cutting thinner metal though, now the machine doesn't crash into the sheet as it warps from the heat, it rides right along with it.

plasma vent!!

FINALLY finished making the ventilation system for the plasma table today. it could probably still use a smaller pulley so the fan spins a little faster, but it at least makes cutting inside possible / tolerable. we still need to put a tarp over the opening to the 2nd floor though, as some of the smoke that rises out of the suction goes up there and then doesn't get vented back down. might be able to fix that with a little more suction on the fan in the future though.

the flexible duct we got compresses a ton, so it doesn't take up very much space at all when not in use. its not very robust though, so i can see it get bunged up over time. love the scraps of leather for handles that we put on the hay chute style door. makes it easier for toshi to try to make his escape.

Tuesday, March 2, 2010

6 hrs

this is the new mantra. this is what i'm working towards. 6 hrs a day of doing what i want to be doing. it won't happen right away, but i need to start making steps towards this. the sign is to make a permanent impression in my subconscious. george made me do it. he's a drawing teacher / life coach / rad dude.

Monday, March 1, 2010

Subscribe to:

Posts (Atom)